A successful Turnaround Maintenance (TAM) increases equipment reliability while reducing catastrophic failures in manufacturing and process industries. This is usually intended to add 3 to 5 years to the plant machinery smooth operations, free of any major maintenance issue.

The successful TAM reduces unscheduled outages while maintaining continued production integrity in industries such as oil and gas refining, petrochemicals, steel plants, power generation and others.

One way of ensuring success in managing the complex events of the turnaround maintenance is to have an efficient plan and schedule - the two critical elements of maintenance. In addition, the managers must utilize the right expertise and tools.

The plan should ensure that there is an effective management of the technical issues, logistics, time and safety. Having a good control of the routine work ensures that the team has the ability and time to deal with unexpected work.

Challenges of implementing a Turnaround maintenance

Controlling the costs and duration of a turnaround shutdown is usually a challenge. Although it lasts a few weeks or months, a major TAM will have a high-intensity workload which almost costs the equivalent of an annual maintenance budget. In some cases, the Turnaround constitutes one of the major maintenance expenses for the plant. This arises from both direct costs as well as huge loss of production during the maintenance period for the oil, gas and petrochemical industries. As such, it is essential to plan properly and ensures that each component is included.

Some of the challenges include;

- Inability to meet the company’s turnaround and business goals

- Cost overruns

- Increased work scope

- Shortage of experienced workers and skills

- Abandonment before project completion

- Organization conflicts

- Turnaround staff stresses

- Not implementing all the recommendations

Innovative tools for planning a successful turnaround and shutdown

Managers can take advantage of the advances in hardware and software technologies to help them succeed in the planning and conducting the turnaround maintenance.

This includes using drones for inspection, IoT sensors to collect data from the machines, data analytics to process the data, and Artificial Intelligence (AI) to learn and predict various conditions likely to occur in the systems. In addition, the managers can use virtual reality and augmented reality to instruct technicians and also avail a wide variety of information and resources. This reduces the time the workers spend on the tasks and hence a reduction in downtime.

Below are the three innovative tools the oil and gas turnaround managers can utilize during job the planning process.

Collecting data using drones and other technologies

A good plan depends on how much data is available. However, collecting some data is sometimes a challenge, especially in complex systems, hard-to-reach areas and remote infrastructure. Getting this data is usually expensive, time-consuming and sometimes risky for the workers. For example, some areas may be contaminated or have toxic gases which present health hazards to the employees.

To inspect these areas, the company may have to spend a lot of money in providing access gear, protective clothing and breathing aids in some areas. The excise will also take longer and can delay the service if there are many locations to inspect. However, the company can cut down on these expenses by employing drones and other innovative technologies such as AI, robots, and Internet of Things.

Drone inspection services reduce the cost and time for carrying out the inspections in both normal and complex structures. In addition, there is no need for the human to go to the difficult locations. This reduces the hazards, hence increasing the safety and reducing other costs such insurance and climbing gear.

The devices use other technologies such GPS, wireless data communications, imaging and photo cameras to collect and send data to ground systems and control rooms. This enables operators to access the inspection data and the actual status of the systems. Such information is useful to the planners and decision makers of the turnaround maintenance, since it helps in minimizing unexpected surprises during the actual service.

The benefits of using drones in the preparations and planning are many. The drones improve the pre-turnaround tasks such as the inspections by reducing the costs, time and risks of performing the exercise. Further, it makes it possible to collect data impossible using traditional manual methods. Once the data is available, the company is also able to plan well in terms of parts, resources, timing, and skills that ensure a minimum downtime.

Drone inspection software tools

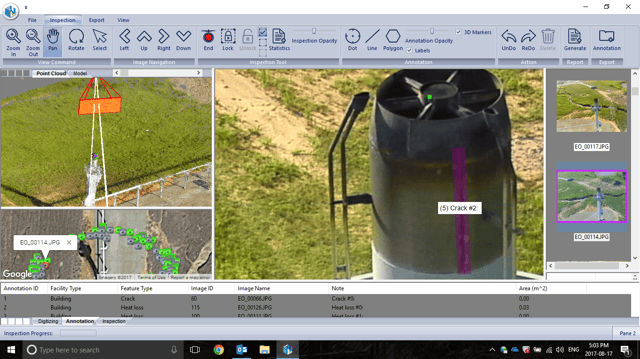

There are several drone software tools for planning and executing turnaround maintenance. One of the most comprehensive drone inspection software is the BlueVu fromIndustrial Skyworks. The software has features such as;

- Automatically and intelligently analyzing, sorting and organizing the images and data from drones

- Enables viewing of data using 3D models

- Providing a faster and better insight about the status of the systems hence making it easier to identify potential problem areas

- Export the drone inspection data to CAD format

- Automatic generation of comprehensive and easy to understand inspection reports, including the visual images, vectorized results as well as the statistics.

- Provides a customized database for recording, organizing and digitizing the anomalies such as cracks, corrosion, hotspots and others directly from the drone inspection images.

The drone inspection software provides a complete solution that enables the maintenance teams to collect and interpret data quickly at a much lower cost. While the drones eliminate the need for a human worker to go to the dangerous locations, the software eliminates the need to have someone manually analyze thousands of images looking for defects.

Applying artificial intelligence and Data Analytics on maintenance data

AI can help companies to predict potential failures and hence respond in good time or prepare properly for the turnaround maintenance. Using historical data, the AI systems can predict a variety of scenarios based on certain conditions. Such predictions will assist the decision makers and planners when developing the scope of work for the turnaround maintenance.

The AI tools enable the organizations to sort through massive volumes of maintenance and performance data. These have capabilities to analyze the data and find patterns that are useful for maintenance purposes.

Using the pattern recognition technologies, the artificial intelligence tools can predict a machine breakdown and even estimate the time when it will occur. This equips the planners with critical information that also helps then to schedule the turnaround or shutdown at the right time before the failures occur.

Some machines play a critical role in the operation of the whole system and should be prioritized. Using data analytics, AI, and other software tools, the planner will be able to predict several things about the operation of a specific machine, components, and systems.

IoT and Industrial Internet of Things (IIoT)

Companies are increasingly using the technologies such as the IOT and IIoT to add intelligence to a wide variety of critical components in the plants and machinery. This enables them to collect real-time data which enables the maintenance teams to assess the conditions and make better data-driven decisions.

Combining the data from multiple sources, the machine learning technologies can predict a failure before it occurs. The planners and maintenance teams should utilize combine several technologies to help monitor the machines and make the right maintenance decisions. Instead of simply using IoT and other technologies to monitor several parameters, companies should use artificial intelligence to provide actionable data from the real-time insights.

Conclusion

The duration and effectiveness of turnaround maintenance are critical for smooth operations and improved company revenues. To ensure minimal costs and downtime the turnaround managers must ensure efficient planning and coordination. However, the time and cost should be the minimum possible without compromising the quality of work.

A good planning ensures a successful turnaround and should consist of the scope, materials, actions, and resources. This together with best practices results in the efficient execution of a turnaround shutdown and a consequent smooth plant startup. To achieve these, the management and planners can use innovative technologies such as drones, robots, IIoT, AI, data analytics and other tools to obtain, analyze and generate actionable data.

Tags

Oil and Gas

.png)