Last month our senior engineer, Brian Kim, accepted an interview from PES Wind Magazine to discover the possibilities of AI, and it advantages it may bring to the wind industry with our digital remote inspection software.

The article is originally published on the PES Wind Issue 1, 2022.

It's lovely to welcome you to PES. We're looking forward to introducing our readers to a new name. With that in mind, perhaps you could give us a brief summary of Qii and your role in the wind industry?

Brian Kim: Qii system is an end-to-end enterprise solution for drone inspections from data uploading to report generation. The system includes Qii studio, Qii connect, and Qii edge. Qii studio is a cloud software integrating data uploading and processing, data sharing, user management, etc. Qii connects, and edge are AI embedded inspection software, web and desktop applications.

My name is Brian Kim. I'm a Ph.D. and a senior software engineer leading Qii edge programming, data processing pipeline, and AI.

Wind turbine inspection methods have traditionally been quite slow and prone to errors. How have you seen this change in recent times?

BK: Traditional inspection methods are mostly human-centric, so they have disadvantages such as slowness, low accuracy, high cost, safety issues and so forth. As the backbone of remote sensing technology, drone imaging is a promising data collection method since it is fast, safe, cost-saving, and detailed. These days, it is being successfully used to inspect diverse industry assets, including wind turbines.

The take up of drone inspections in particular has been fast paced hasn't it?

BK: Yes, it has. According to the report published by Allied Market Research, the global drone inspection and monitoring market generated $6.44 billion in 2020 and is anticipated to reach $35.11 billion by 2030. This projected market growth results from the need for increased cost-efficiency & safety, reduced risk, and high quality of records which are benefits of drone inspection.

How has the development of AI helped to move things forward?

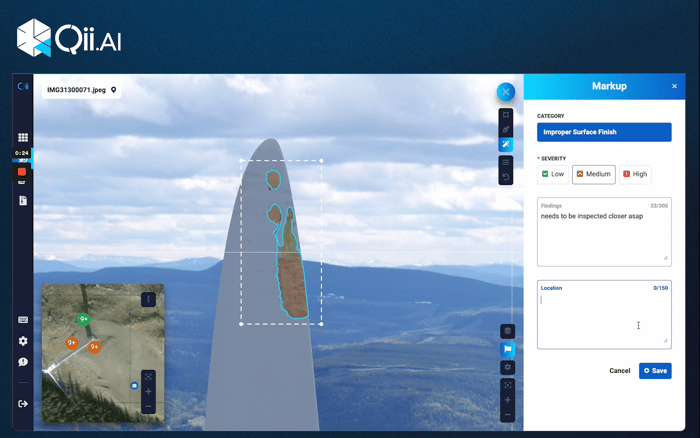

BK: Todays, many manual processes and works in industries are being replaced with AI since AI reduces human errors and risks, makes decisions faster than humans, and increases business efficiency. In drone inspection services, AI is applied to automatically recognize, categorize, and measure defects from drone images. Humans are only required to make a true or false decision to confirm defects detected by AI. Thus, AI dramatically decreases human interventions in asset inspection. AI also has contributed to new drone inventions, such as a drone attaching a water spray nozzle to clean insulators in power line corridors. In this application, AI needs to identify the insulators from every video frame on the fly so that the drone precisely sprays water toward them. Such that, AI has helped to start new drone businesses and increase the efficiency of existing businesses.

What do you see as the main advantages of using AI for wind turbine inspection, both on and offshore?

BK: We expect that AI automates the following inspection processes:

- Detection of wind turbine anomalies

- Defect categorization

- Estimation of severity level

- Measurement of the defect area

- Change detection from multi-temporal data

Such AI's ability brings key advantages for wind turbine inspection: speed up the inspection process, increase accuracy, save labour cost, and ease the workload.

What kind of things can AI help to track?

BK: Please clarify your question. It seems that your question is about what AI can track, such as monitoring the movement of the turbine blades.

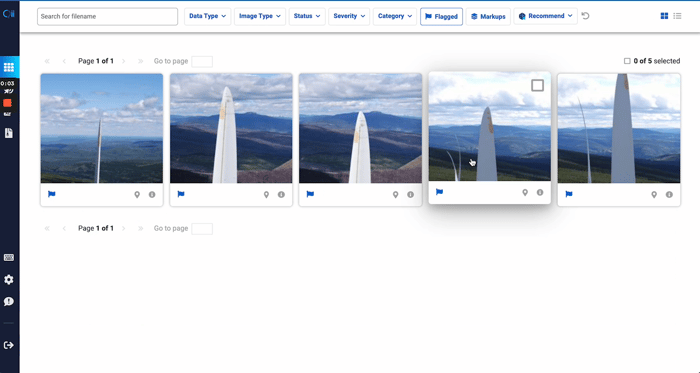

Presumably, once gathered, the data can be shared and analyzed quickly and easily between the necessary teams, which must also save time?

BK: Data sharing is an essential requirement in inspection applications to share observations, analyses, and reviews between collaborators. Qii system has the feature called Qii link for sharing reconstructed data (i.e., 3D digital twins) and defect detections as well as raw images with a single click. It saves time and secures data since physical data transfers are not necessary. Qii link has participant roles in managing the data accesses to invitees, including viewer, inspector, and admin. The functions are customizable. In addition, inviters can specify data to be exposed to invitees.

Is the data still prone to error though?

BK: Most errors originally occur from data processing due to poor data acquisitions, which are. For example, insufficient overlaps between drone images fail to create 3D digital twins, and image corruption caused by sensor malfunctions hinders AI detection. Such that, it is important for drone pilots to follow the drone operator guideline. Others would be errors in AI detection which will be evolving and improving by feeding more data.

Is this technology specific to drone inspections or can it be used in other ways too?

BK: Qii system has been initially designed for drone data processing and inspection. However, the system can handle any images captured with and without geotags once they comply with data acquisition guidelines. It also supports a combination of multimodal cameras such as images captured from airplanes, drones, and the ground. In addition to visual inspection, thermographic inspection with images taken by thermal cameras is applicable.

It sounds as if one of the biggest benefits of all this is increased efficiency, not only in terms of the inspection process itself, but also in the operation of the turbines themselves as a consequence of the data gathering and analysis?

BK: Traditional inspections and maintenance activities require high expense and undesired downtime of wind turbines, while the drone-based method maximizes turbine uptime and performance by saving both time and money.

Are you finding much resistance to the use of AI or is the sector on the whole quite happy to embrace it do you think?

BK: Customers do have valid concerns on items such as data securities but generally welcome the changes as it brings value and efficiencies in their work.

This is a fast developing market, but what do you think the next 12 months or so may bring? Are there even more advancements and even greater benefits still to come?

BK: We have a vision that remote digital inspection should be as good or even better compared to the inspection performed onsite. We are incorporating Augmented realities into Microsoft HoloLens for better inspection results.

And for Qii; what might our talking point be the next time we speak do you think?

BK: AI sovereignty and AI competitiveness - We believe AI will be core competitive advantage for many inspection companies.

About PES:

PES has for a number of years, been regarded as a leading trade publication across both the Solar/Photovoltaic and the global wind market, both onshore and offshore. Having been established in 2005 PES continues to deliver cutting-edge insight & technical analysis of the key issues & topics affecting the markets around the world, through its sister titles PES Wind & PES Solar/PV publications, produced quarterly.

To access the full digital issue, click here.