Creating digital twin is an effective solution enabling energy companies and other businesses to optimize operations and reduce costs. It can improve operations in the entire oil and gas ecosystem, from exploration and extraction to delivery and distribution. Generally, the digital twin can help the companies to respond to various challenges, and make better data-driven decisions that optimize performance and correspond to prevailing geological, environmental, and market conditions.

Generally, to remain competitive and optimize the systems to respond to market dynamics and uncertainties, energy companies should deploy technologies that provide them with real-time visibility into their assets. Towards this, the digital twin provides valuable insights while predicting outcomes based on certain scenarios. Ideally, it helps the companies to build models that can predict what will happen if something happens. These models often give answers to questions such as 'What will', What if' etc.

In practice, the digital twin for the oil and gas is dynamic as it allows the operators to see the various physical assets at the drilling and other sites, along with all their relevant data. Typical information they can obtain includes the real-time flow rate of a particular well. They can then compare with historical data such as the average flow rate over the last one month or week.

Teams can also determine the time the field assets are due for major maintenance and other minor preventive measures such as removing the paraffin and cleaning the boring equipment.

Generally, organizations can use the digital twin to gain knowledge about the assets, hence optimize them and add more service life to the equipment.

Typical benefits include improving efficiency, predicting failures, improving maintenance, and reducing downtimes.

What is a digital twin?

A digital twin is a combination of technologies that replicates the physical asset into a virtual model. It uses data to analyze a situation, make predictions and sometimes perform automated processes.

In practice, a typical digital twin incorporates all aspects of an asset from the design phase to the real-time status and performance. It allows the operators to evaluate operational opportunities, solutions to challenges, pricing, logistics, safety, hazards, and production optimization methods. Further companies can use technology to identify and test various solutions including their impact on the overall performance.

Simply put, a digital twin just like the human twins, refers to the digital copy of a physical asset and is a useful technology in almost any industry including oil and gas. It pairs the physical and virtual models, and this allows businesses to monitor their systems, analyses data and streamline or optimize the operations throughout the service life of the asset.

The technology helps to improve operations, reduce costs, and prevent downtimes. Ideally, the digital twins prevent costly mistakes and potential rework by allowing the team to simulate the possible outcomes based on a set of inputs corresponding to real-world situations.

In practice, the digital twin's technology replicates a part of the whole asset into a virtual model in which businesses can run simulation tests based on real-world conditions, or problems, after which it provides results in 3D visualizations. Consequently, it allows technical people to understand and optimize an assist, hence ensure its performance corresponds to the market needs.

Also, the digital twin is like an archive of the asset's real-time data such as condition monitoring, predictive analytics, failure diagnostics, and more information acquired using sensors and other technologies. It also has contains historical information such as the models, manufacturing data, bills of material, drawings operational history, and more.

Asset Inspection data

Data is useful in determining a wide range of outcomes. Along with other technologies such as artificial intelligence, machine learning, big data, analytics, and more, analyzing the data provides useful insights and the opportunity to make necessary adjustments.

For effective outcomes, the digital twin requires accurate, quality, detailed and reliable data. The information comes from multiple sources including sensors integrated into the assets as well as external sources such as drone surveillance, visual or manual inspections, etc. Ideally, the technology relies on a broad set of information including part numbers, specifications, operational data, environment, and others.

Generally, the companies can obtain and predict the operational status of the assets by collecting and using data from multiple sources as the input to the models. Typical sources include inbuilt sensors, SCADA, drone surveillance or inspection data, remote sensing, visual inspections, and other inputs.

By using the data as input to the models, the operators can determine how the physical assets in the oil and gas facilities perform in real time. Further, the modeling allows the operators or technical teams to conduct what-if simulations and see how the real assets and processes would perform or respond under various potential conditions.

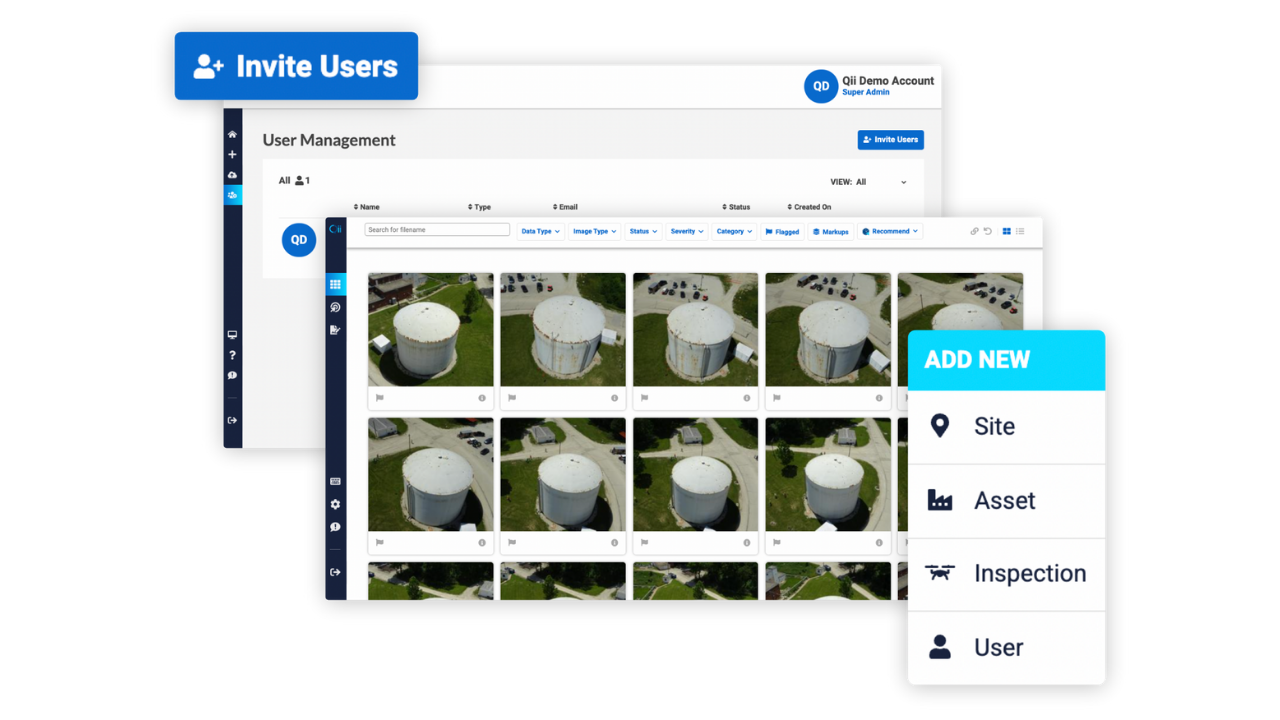

After creating a digital twin, it is vital to ensure that it has up-to-date data reflecting the current status of the asset, including any changes. Ideally, real-time monitoring and simulations help to provide the accurate status of the asset. Using drones, the oil and gas companies can perform regular inspections of their onsite and remote field assets hence ensuring that the digital models are based on the current information.

How digital twins can help the energy industry

Ideally, the digital technologies enable the companies to model and plan their drilling and operations better, improve asset management and predictive maintenance. Considering the complexity of the oil and gas exploration and extraction activities, the digital twins come in handy in providing useful insights that consequently paves way for more data-driven decisions and actions.

Consequently, these allow the companies to optimize their activities in the entire ecosystem from where to drill and extraction methods to processing and delivering the products.

The technology can simulate the procedures, detect anomalies in the assets or processes, and automate the repairs. It also enables the oil and gas companies to anticipate and resolve potential problems hence prevent failures and downtimes.

Improve Predictive maintenance

Using advanced inspection data, the digital twins have the potential to detect degradation and early signs of impending equipment failure. Consequently, it helps the company to be proactive, and move from the traditional way of taking action or responding to failures after they have happened. Ideally, it allows the technical teams to plan and perform corrective maintenance before failures.

By continuously monitoring the assets using a wide range of inbuilt sensors along with frequent drone inspections, the companies can collect a wide range of information from the assets. Feeding the data into the digital twins enables them to gain insights, identify and resolve various performance and maintenance issues before failures.

Doing this is not only less costly but prevents downtimes and lost productivity, more damage due to failed components, etc.

Monitor and Gain visibility into assets and operations

The companies can use various sensors and technologies such as IoT, drones, automatic and manual methods to inspect assets and gather real-time data. This allows them to understand how the rigs and wells are performing in real-time while providing opportunities to adjust and optimize the systems and procedures to improve performance.

Using sensors and other technologies, the digital twins allow the technical teams to gain visibility, obtain real-time data, and understand the state and condition of their assets. Luckily, drones, robots, sensors, and various communication technologies spanning the public and private networks allow the remote monitoring of assets. For example, they can monitor their oil wells and use the geological data and productivity trends to optimize or adjust their operations to ensure consistency in the output.

Additionally, inspecting the assets remotely helps to improve productivity at reduced costs. Teams can remotely monitor operations, assets, environmental conditions, and other parameters that impact the processes and productivity. Consequently, the energy companies can perform frequent, cost-effective virtual inspections that reduce the site visits, manpower requirements while saving them time and money.

Simulate new products, technologies, and processes

Besides providing insights into existing systems and processes, manufacturers and technology providers can use digital twins when building new products. For example, they can try out a new feature and see its impact before taking the product to the market. As such, using 3D models and various real-world inputs, designers can determine the impact of new features and find out how to make improvements on the digital model before producing the physical model.

The digital twins offer a sandbox where energy companies and technology providers can try out a wide range of opportunities. It provides the necessary tools that enable other stakeholders in the energy ecosystem to test new products, services, and configurations. The vendors can for example use the digital twin’s ecosystem to evaluate their product's performance in a simulated environment. Additionally, the platform offers the partners to collaborate and verify that their solution can address a specific problem.

Improve extraction planning

By obtaining and analyzing the geological data and oil rig metrics using the digital twins, the energy companies can understand the production sites better, identify opportunities that enable them to improve the drilling operations. The technology also allows them to streamline their operations and safety at the sites.

Ideally, the digital twins enable the oil and gas companies to maximize every component of their operations. It helps them to identify the best way to drill, maximize the extraction processes, and enhance safety among many other things that help them to optimize their activities.

Future of digital twins and challenges to overcome

Today, the digital twins are playing a major role in transforming how energy companies address most of the business challenges and hence help them to unlock many opportunities. The technologies help businesses to create value and enable better integration across assets, teams, and stakeholders in the value chain.

As the technologies mature, the industry will interconnect multiple digital twins with each other to provide exponentially higher and more comprehensive insights that will enable more analysis, understanding, and optimization of complex operations.

In the future, the digital twins are likely to expand to more applications in the oil and gas industry as it combines with other emerging and mature technologies. Combining it with artificial intelligence augmented reality, IoT, IIoT, virtual reality, and other technologies will provide more optimization and cost-cutting opportunities.

Despite the opportunities, the digital twin offers, a few challenges such as lack of standardization, awareness, understanding of the technology, and others issues are hindering wide-scale deployments.

Conclusion

The digital twin refers to the virtual replica of a physical asset or process. Typically, this goes beyond a 3D model to include all the relevant information about the asset or process. The technology, usually computer software, relies on real-world data to simulate various conditions or outcomes that show how an asset would perform under a certain real-world input. It can present a holistic representation of the physical object or process under study.

It enables the different departments and stakeholders to collaborate, create new opportunities, respond to performance challenges, improve efficiency and prevent downtimes. For example, before manufacturing, add features to, or modify a product, designers can first create a 3D virtual model, test it under various conditions to determine how it will function. That is, instead of building and testing the physical models, the manufacturers will first work with a virtual model. The digital twin approach helps to reduce costs, time, and mistakes and rework on products.

Also, the digital twins can reduce the risk of unplanned downtimes due to sudden failures, prevent accidents, and reduce operational and maintenance costs, hence improve efficiencies and revenues. Finally, the digital twin provides opportunities to streamline products and services, hence deliver positive business outcomes.