Compressors, pumps, turbines and motors are common rotating equipment in Oil and Gas installations as well as petrochemical plants. Such rotating equipment is, more often than not, handling flammable fluids and running in an environment where possibility of existence of flammable vapors (from spill or leakage) cannot be ruled out.

Under such scenario the most catastrophic occurrence that may be faced is fire occurring either from an electric spark in the control panel / main distribution board or from extremely over-heated rotating equipment due to misalignment.

The basic fire hazard reality that one should keep in mind while tasked with operations or handling of hydrocarbons is described in following points:

- Flash Point of hydrocarbons is in the range of -135o C (methane) to 200o C (pyrene). Flash Point is the lowest temperature at which vapor of a volatile material can be ignited WITH an ignition source present.

- Auto Ignition Temperature of hydrocarbons is in the range of 200o C (N-decane) to 595o C (methane). Auto Ignition Temperature is the temperature at which a material spontaneously ignites in a normal atmosphere WITHOUT an external source of ignition.

It is well known that despite technological developments and precise machining the alignment and assembly in industrial machines cannot be expected to be perfectly ideal. Bearings and journals often wear out due to poor lubrication, misalignment or shaft deflection and such situation, if continue, causes excessive friction and extremely high temperatures – approaching or exceeding auto ignition temperatures.

Modern high speed machines use Tilt-pad-journal bearings to accommodate for wear resulting from pivot offset, bearing clearance, length of the bearing, and preload thus optimizing factors like power loss, temperature and dynamic performance. Another latest technology is Active Magnetic Bearing (or AMB) used in high speed rotating machinery.

AMB uses electromagnetic forces to levitate a rotating shaft in space, and maintains its position by actively controlling the current supply to electromagnets. In this way ‘zero contact’ is ensured between the bearing and the rotating mass – friction-free operation, and a clean, reliable and efficient machine.

Additionally, AMBs come with machine health / condition monitoring software and a continuous vigil is enabled to monitor, identify and analyze the status of important conditions such as anomalous temperature and vibration in rotating machines.

This information can be used to set alarms and schedule maintenance. Remote bearing monitoring capabilities helps operators recognize and head off potential trouble before it starts. AMBs are not feasible for all rotating machines.

NEMA 250-2014 and IEC 60529 not only provide classification of enclosures used for indoor and outdoor hazardous class locations but also suggest guidelines for use of these enclosures for protection against explosion and ignition. Following the guidelines provided by these standards is mandatory for minimizing the fire and explosion risks associated with an environment containing hydrocarbon or volatile vapors.

However, these standards do not cover the requirements for protection of the enclosed equipment against conditions such as condensation, icing, corrosion, or contamination, which may occur within the enclosure or which may enter via conduit or unsealed openings.Additionally, the human factor cannot be eliminated where instances of loose connections are identified to result in electric spark.

Whether it is misalignment or a tiny electric spark, the result is an ignition source and abnormal rise in temperature which is not detectable by human senses, especially when at a location difficult to access or view. The presence of hydrocarbon vapors in such a condition can trigger one of the two phenomena explained above i.e Flash Point Ignition or Auto Ignition.

IRT and INSPECTION DRONES CAN HELP

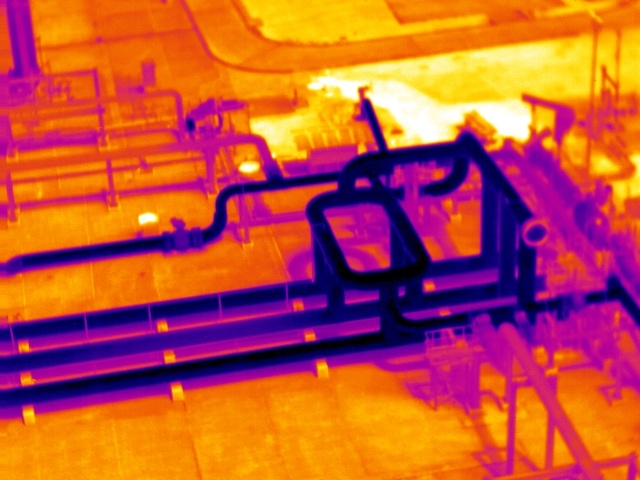

Using Infrared Thermography during periodic inspection can help in capturing multi-spectral images of plant equipment and electrical panels to identify anomalous high temperatures. The thermal signature on a portion of equipment is identified to be different from the rest of the equipment – an indication of anomaly and possible misalignment or spark occurrence. By installing IRT sensors on drones it is possible to inspect those areas of an Oil and Gas asset where rotating equipment is running and which are not easily accessible otherwise.

The inspection ability of operators of oil and gas facilities is often limited by high cost and access issues. Inspection drones can help detect anomalous high temperature conditions in a cost effective and safe manner through drone mounted IR cameras.

IRT helps pinpoint potential problems with loose and corroded connections, electrical imbalance, failing transformers and switchgear and faults in motor control centers. Checking motors and drives to see if the motors and associated panels and controls are operating too hot.

Similarly, inspecting of bearings can also be carried out by IRT by recording bearing and housing temperatures and then comparing current operating temperatures with benchmarks to detect potential failures in time to prevent accidents. Electrical distribution panels, control panels and high-speed rotating equipment IRT Inspections are perfect means of application of the diagnostic capability of Thermography.

Additional features that get enabled with the use of Industrial Skyworks drone mounted periodic IRT inspection are the recording and processing of such data collected over time from the same equipment. The valuable time-trended information provide efficient “machine learning” to the benefit of the asset manager / operator.

Industrial Skyworks drone technology is turning the cumbersome maintenance effort into a safer and more streamlined data collection process for implementing maintenance management systems – in line with and complementing management systems based on ISO 9001 (quality), ISO 14001 (environment), or OHSAS 18001 (occupational health and safety).

The bottom line is that the combination of back-end support (like data analyses and processing capabilities), low cost examination and safe access capabilities of inspection drones are making them a useful tool for minimizing operational risks.

Their invaluable data gathering capability is helping decision makers take timely and informed decisions on the maintenance requirements and frequency of inspections. Benefits come in the form of overall mechanical integrity and safety of Oil and Gas assets.

Tags

Oil and Gas

.png)