Drones have proven to be the best tool for inspections of many large industrial and other assets such as power generating plants, oil refineries, bridges, and all manner of similar infrastructure. As this approach has become immensely popular owing to the rate of image capture and quality of the images, we take a closer look at our Qii Vision Inspection Platform and how it can help in high-quality asset inspections.

Drones for industrial inspection

Drones have proven to be the best tool for inspections of many large industrial and other assets such as power generating plants, oil refineries, bridges, and all manner of similar infrastructure. As this approach has become immensely popular owing to the rate of image capture and quality of the images, we take a closer look at our Qii.AI, Vision Inspection Platform, and how it can help in high-quality asset inspections.

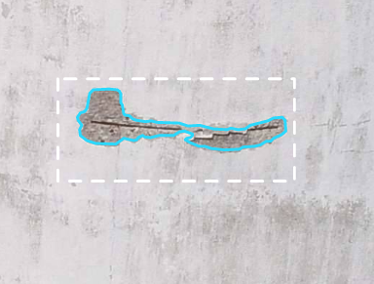

We could use drones for efficiently collecting thousands of high-quality images of an asset. Once the data is collected, the domain expert would go through all these images and identify all the anomalies in the asset. During this process of an inspection, annotating anomalies at pixel level accuracy is especially important for assessing the severity of the anomaly. If done manually, this process would be very time consuming and therefore expensive. For example, annotating a crack boundary would be incredibly challenging as it would have many branches with thin edges. Also, when it comes to visual inspection, missing a critical anomaly in an asset is not at all acceptable. In many scenarios, the visual inspection is subjective, and it needs human involvement to make the right decision. Considering all these factors, we designed an AI-driven interactive visual inspection platform that actively involves a human along with Artificial intelligence.

Computer vision for visual inspection

Many traditional computer vision algorithms have been proposed in the past for automatic detection of anomalies like corrosion, cracks, and other types of anomalies. However, it requires task-specific parameter-tuning when it deploys to real-world enterprises. The recent advances in deep learning have revolutionized many computer vision tasks like object recognition and segmentation. Deep neural networks achieve optimal performance when trained with a large set of labelled data. Specifically, given a task of corrosion detection, the neural network needs to be trained with a large number of annotated samples of corrosion data. However, collecting and annotating enough samples of corrosion data from the given asset is time-consuming and laborious. For many scenarios especially in the asset inspection industry, sufficient data for the new task may not be available due to the less frequent occurrence of anomalies and because of privacy concerns. Another challenge for the automation of visual inspections is scaling up trained models for new object classes, as current approaches lack the capability to add new classes of objects without retraining the model with the new data, adding a need for more time and resources. In addition, the model should be able to handle the domain shift in the data. For example, a model trained for segmenting cracks in pavement should be able to segment cracks on a metal surface as well in order to be as useful as possible in real-world scenarios.

What is our proposed solution?

Compared to other AI systems which are trained for a specific task, our Qii.AI platform provides a generic and efficient AI-driven interactive inspection tool that can segment every anomaly that the user selects, on the fly. This platform facilitates easy collaboration between human and machine intelligence by allowing the user to review the AI-predicted segments with a few user clicks. In other words, our interactive visual inspection tool allows the user to interact with the AI system to improve the performance instead of completely removing the human from the workflow. Our tool supports segmentation of anomalies such as corrosion, cracks, coating breakdown, etc., in addition to segmentation of all generic objects, allowing our intelligent platform to reduce inspection times drastically. The whole inspection process can be done without the hurdles of time-consuming data annotation and training for each anomaly type.

How to use the tool for inspection?

In the proposed solution, the user can select the region to be inspected with a bounding box. The AI system automatically segments all the anomalies in the selected region. It selects all the instances, if there are more than one instances in the region of interest. The inspector can make the corrections to the prediction by clicking on the segmented region or adding or removing new pixels. The deep neural network predicts and adapts according to user- interaction. In some scenarios, the AI system may not be able to predict anything on its own if the selected region doesn’t have include any salient objects. In that case, the user can initiate the segmentation with a mouse click on the object of interest. The algorithms are designed to get accurate and efficient pixel-level segmentation with few user-clicks. The inspection tool can be used for segmenting any size of objects ranging from big patches of corrosion on the surface of a storage tank to thin cracks in the cement façade of a dam, increasing both the speed and accuracy of asset inspections..